Descriptions

Specifications

Titanium investment casting parts,investment casting bicycle parts

Titanium Casting Parts for spectacle frame

1.Ti content 45.99%-99.99%

2.Material:Gr1, Gr2,Gr4,Gr5, Gr7, Nitinol

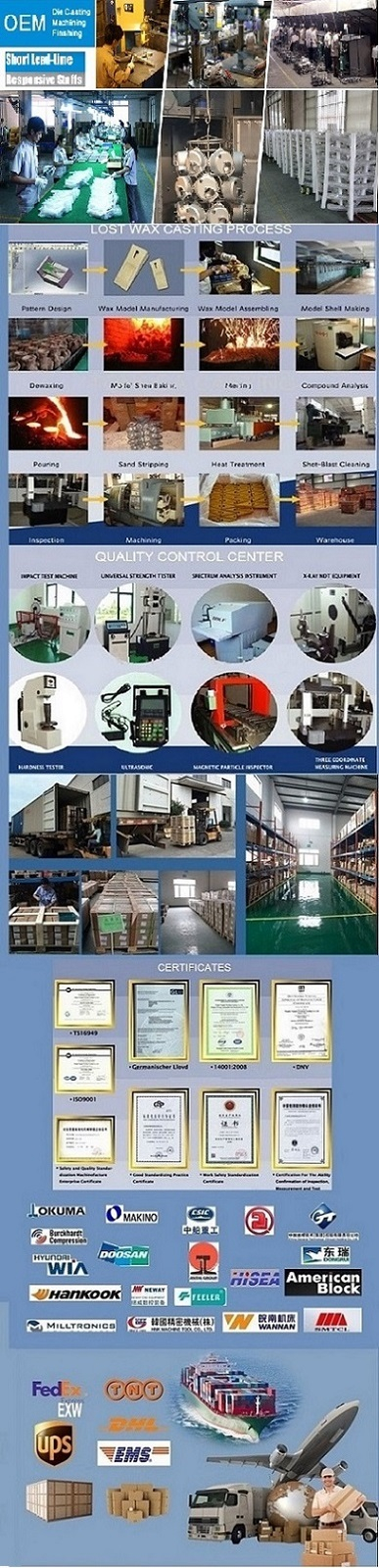

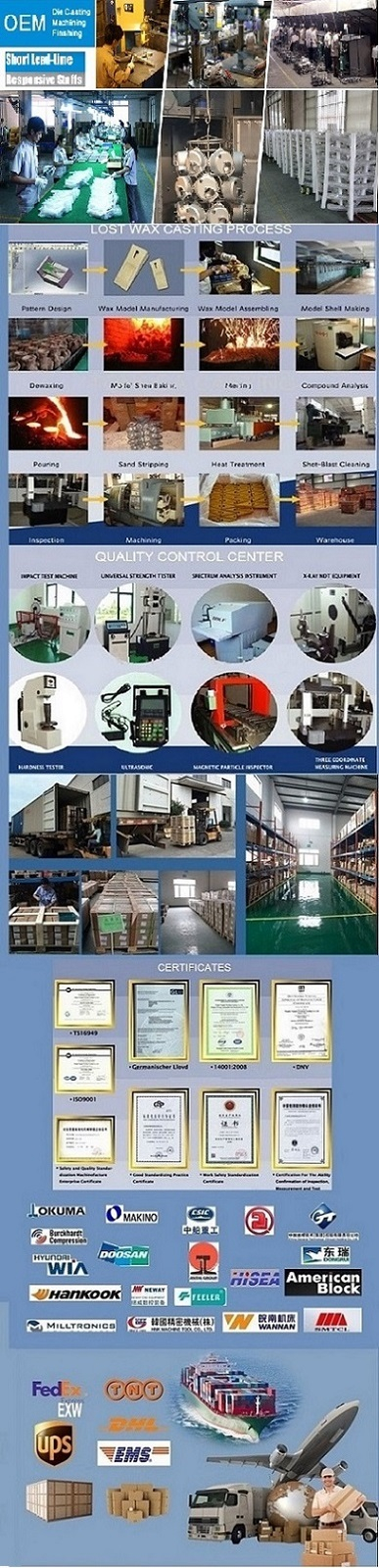

3.Custom

Titanium Investment casting parts / Precious Casting for spectacle frame

1. Material: From: Gr1,, Gr2, Gr3, Gr4, Ti-6Al-4V, Gr5 ELI , Gr7, Ti-3Al-2.5V, Nitinol Shape Memory Alloy

2. Specifications: as per drawing and client requests.

3. Standard: ISO, GB, ASTM, DIN, JIS etc

4. Surface treatment: Polished, Machined, Picking, Anodised, Color burnt, Homogenization heat treatment, Sand blasting, Painting, Electro-plating, Chemical Plating, and other machining processing.

5. Characteristic: Non-magnetic, light Weight, high strength, excellent corrosion resisting

6. Producation Process: Drawings→ Mould making →Raw casting → Sandblasting →Rough machining or Finish machining →Surface treatment →Product checking→ Packing →Delivering

7. Quality Control:

- Mill Test report

- Chemical composition & Mechanical properties Test Report

- Third Party Inspection

Casting:

1.Steel casting,investment casting,aluminum casting, zinc casting,die casting,sand casting,stainless steel casting.

2.OEM,can be customized.

3.Alloy, Aluminum,Brass,steel ,copper,stainless steel,mild steel,carbon steel.

4.Durabl

5.Tolerance Control: from +,-0.003MM

6.After-sales-service: take 100% responsibility for any quaulity issues!

Our Advantage:

1.Good Quality

2.Competitive Price

3.Long production history

4. International Quality Certified

5.Skilled workers

6.Prompt Delivery Time

7.Warranty After-sales-service

Titanium investment casting parts,investment casting bicycle parts

Titanium Casting Parts for spectacle frame

1.Ti content 45.99%-99.99%

2.Material:Gr1, Gr2,Gr4,Gr5, Gr7, Nitinol

3.Custom

Titanium Investment casting parts / Precious Casting for spectacle frame

1. Material: From: Gr1,, Gr2, Gr3, Gr4, Ti-6Al-4V, Gr5 ELI , Gr7, Ti-3Al-2.5V, Nitinol Shape Memory Alloy

2. Specifications: as per drawing and client requests.

3. Standard: ISO, GB, ASTM, DIN, JIS etc

4. Surface treatment: Polished, Machined, Picking, Anodised, Color burnt, Homogenization heat treatment, Sand blasting, Painting, Electro-plating, Chemical Plating, and other machining processing.

5. Characteristic: Non-magnetic, light Weight, high strength, excellent corrosion resisting

6. Producation Process: Drawings→ Mould making →Raw casting → Sandblasting →Rough machining or Finish machining →Surface treatment →Product checking→ Packing →Delivering

7. Quality Control:

- Mill Test report

- Chemical composition & Mechanical properties Test Report

- Third Party Inspection

Casting:

1.Steel casting,investment casting,aluminum casting, zinc casting,die casting,sand casting,stainless steel casting.

2.OEM,can be customized.

3.Alloy, Aluminum,Brass,steel ,copper,stainless steel,mild steel,carbon steel.

4.Durabl

5.Tolerance Control: from +,-0.003MM

6.After-sales-service: take 100% responsibility for any quaulity issues!

Our Advantage:

1.Good Quality

2.Competitive Price

3.Long production history

4. International Quality Certified

5.Skilled workers

6.Prompt Delivery Time

7.Warranty After-sales-service

Specifications: | |

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Manufacture: | We use With advanced technology, unmatched skill, professional and advanced equipment size range from 15T-2500T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service |

| Product Material: | Stainless steel, carbon steel, aluminum, brass, zinc,titanium,and so on |

| Making process and Capability: | Progression die, Stamping, deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, CNC machining, Casting,Forging,Laser cutting,Metal Fabrication,forming,spinning, CNC Punching, Plasma cutting, Goffered, Stretch forming, Riveting, deep drawing, Mig Welding,Assembling, Shearing, Blanking, CNC Bending............, |

| Surface treatment: | Anodizing, Powder-Coating, Zinc-Plated, Chrome coated ,Nickel Plated ,Hex Chromates Zinc, Rust-inhibiting oils, Electrophoresis, Paints and primers, blacking, etc |

| Price Terms: | FOB NINGBO OR SHANGHAI, CHINA |

| Lead time: | 20-50days based on the different products |

| Packaging: | canton case or as per customers' requirement |

| Certification: | ISO9001:2008 , SGS , TS16949 |

| Industry: | these parts are used in Automotive, Electrical, Building, Furniture, Machine assembly, Computer, Air industry , Oil field Equipments, Marine equipments, Mine equipment,Agricultural Machines,Transportation Equipments, OEM/ODM Electronics...... |